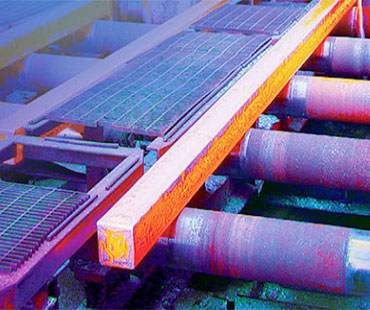

Hot Billet Weighing System

Hot Billet Weighing System

Billet weighing system is customized to fit in to existing roller table. In highly challenging milling environment, yield optimization, consistency in length/weight performance, and scrap reduction are all critical to the operation's success. Through re-heat, customer rejection, and extra annealing energy, incorrect or unpredictable billet length and weight cause waste and energy expenses, depleting the caster and post-processing lines of volume. Extra handling boosts the cost per tonne above the budgeted amount.

It is a fully integrated billet weighing and cut optimization system that enables for weight-based billet cutting in rolling mills and reduces scrap rates. It can weigh billets on conveyors as well as systems that require the billets to be lifted for weighing.

Key Features

- Torch Control

- Reliable Length Control Implementing Better Sensor Technology

- PLC Based System with Open or Dedicated

- Selection of Cut an Optimization Method/li>